Electric mobility is becoming increasingly successful and puts the highest demands on materials in terms of safety, battery range and charging performance. Busbars play a key role here, replacing heavy cables and enabling a higher charging capacity. With Grivory, Grinova and Grilamid, EMS-GRIVORY offers innovative high-performance polymers that provide tailor-made solutions for these core components in the high-voltage range - compact, durable and cost-efficient. OEMs and suppliers benefit from approved materials, which provide weight and cost savings while ensuring maximum voltage resistance, constant insulation and long-term safety.

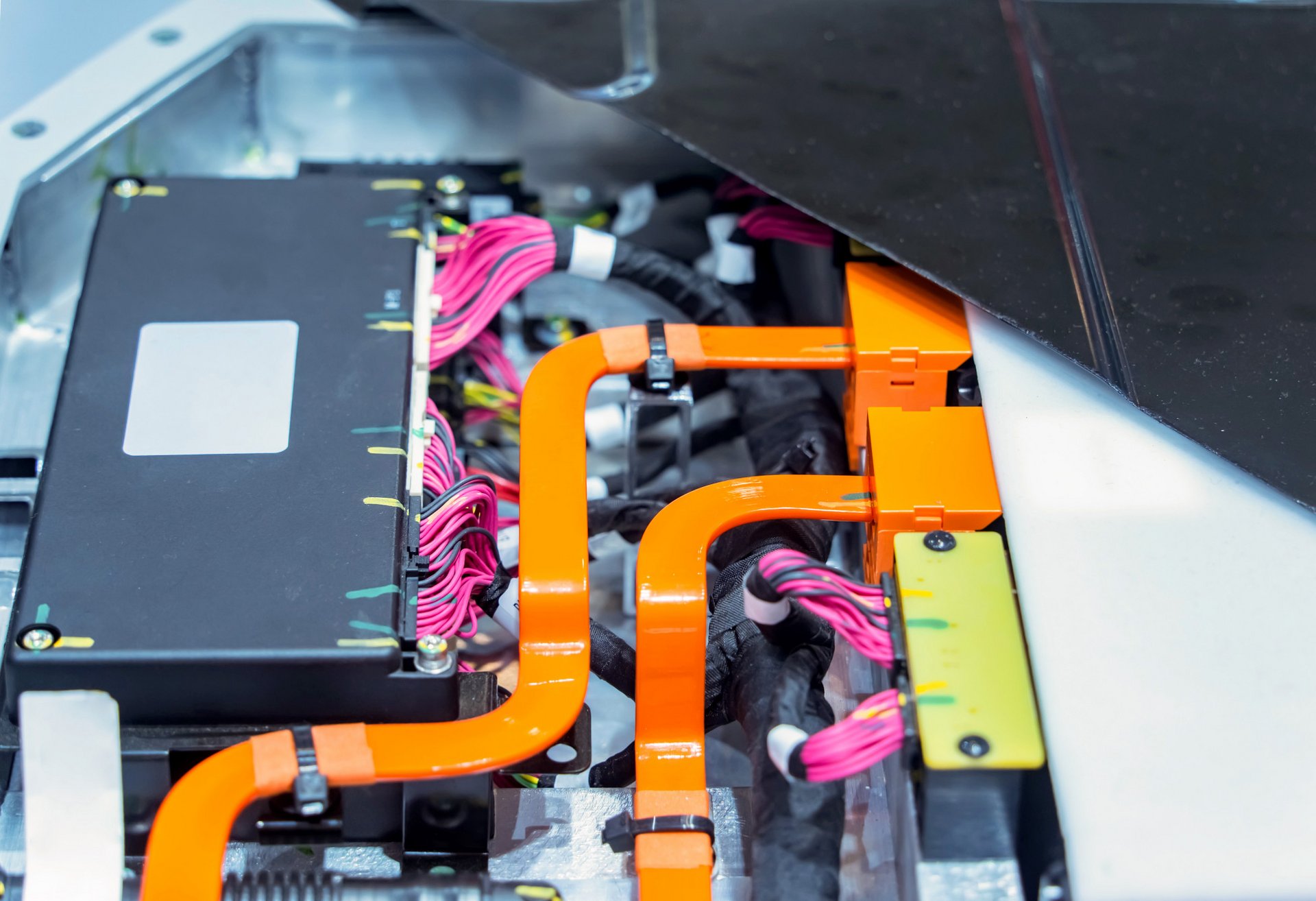

The patented EMS solution for busbars at voltages up to 1,000 V and temperatures up to 130 °C

Cooling water pump for electric vehicles made of EMS high-performance polymer Grivory HT

Electric mobility is becoming increasingly successful and puts the highest demands on materials in terms of safety, battery range and charging performance. Busbars play a key role here, replacing heavy cables and enabling a higher charging capacity. With Grivory, Grinova and Grilamid, EMS-GRIVORY offers innovative high-performance polymers that provide tailor-made solutions for these core components in the high-voltage range - compact, durable and cost-efficient. OEMs and suppliers benefit from approved materials, which provide weight and cost savings while ensuring maximum voltage resistance, constant insulation and long-term safety.

The demands placed on materials in electric vehicles are increasing with each new generation of vehicle: greater range, shorter charging times and more powerful batteries. With its broad product portfolio, EMS-GRIVORY lays the foundation for safe and efficient e-mobility — from high-voltage systems as well as drive and battery modules to charging infrastructure.

Busbars are indispensable in modern electric vehicles. They reduce weight and space requirements, replace heavy cables and enable high charging capacity Using its Grilamid product range, EMS-GRIVORY supplies tailor-made, lightweight, reliable and economical extrusion solutions for busbar insulation. The first generation has already proven itself at voltages up to 600 volts and temperatures up to 105 °C. The globally patented second generation of these materials achieves a new level of performance reliable up to 1,000 volts and 130 °C, with constant insulation properties, corrosion protection and long-lasting heat resistance.

EMS' materials combine excellent dielectric strength with constant electrical insulation, even at high temperatures and in humid environments. At the same time, they provide protection for the metal conductor against corrosion and ensure reliable performance throughout the vehicle's entire service life. This makes them the ideal solution for safety-critical high-voltage components such as charging cables between the connection and the converter.

A further example of efficient metal-replacement using high-performance polymers from EMS-GRIVORY are cooling water pumps for electric vehicles. These must have a working life of at least 30,000 hours and were previously made of aluminum. With hydrolysis-resistant Grivory HT, these pumps can be manufactured 30% lighter in weight and at up to 50% lower cost. At the same time, the motor housing and control electronics are integrated into the protective housing made of Grivory HT (PPA).

Whether busbars, cooling systems, battery carriers, or charging infrastructure, EMS-GRIVORY supplies proven high-performance polymers that ensure safety, efficiency, and sustainability in electric mobility. OEMs and suppliers worldwide already rely on Grivory, Grinova, and Grilamid to achieve cost and weight savings while meeting the highest standards of safety and durability.