EMS-GRIVORY high-performance polymers are ideally suited for metal replacement, in particular in automotive, mechanical engineering and sanitary applications. Based on successful development partnerships with EMS in the field of metal replacement, high-performance polymers from EMS-GRIVORY are now also being used in a wide range of medical technology applications. Examples include biocompatible respiratory devices, precision surgical instruments, complex hearing aids and self-injection devices, ergonomic mobility aids, and many other applications.

EMS-GRIVORY high-performance polymers are ideally suited for metal replacement, in particular in automotive, mechanical engineering and sanitary applications. Based on successful development partnerships with EMS in the field of metal replacement, high-performance polymers from EMS-GRIVORY are now also being used in a wide range of medical technology applications. Examples include biocompatible respiratory devices, precision surgical instruments, complex hearing aids and self-injection devices, ergonomic mobility aids, and many other applications.

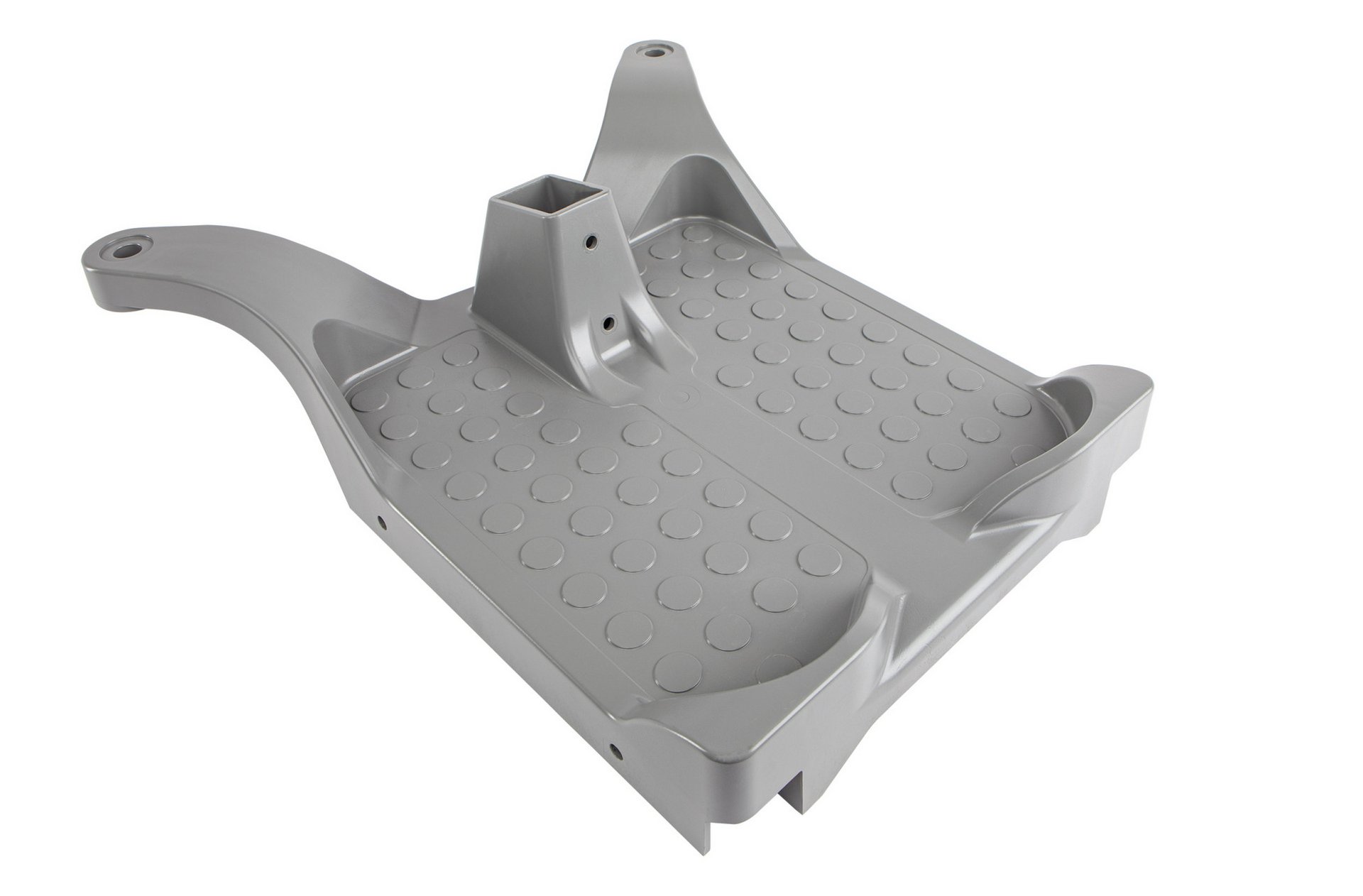

One example of such a successful development partnership is the standing platform for a stand-up patient transport unit. This medical application allows easy and comfortable transport of patients in a standing position without complications. In this particular application, the existing design was reviewed with the customer and optimized with a promising concept. Previously, the standing platform was made of heavy and costly aluminum components. Using detailed simulation and calculations, EMS modelled component behavior and presented the customer with a new and innovative application using EMS specialty polymers.

To achieve this, our calculation engineers always refer to the customer's material requirements and develop a design suitable for implementation using polymer materials. The fastening points were designed as part of the main component, an integration of function made possible by development support provided by EMS. This enables faster assembly of secondary components and a reduction of the overall number of parts, which in turn saves further manufacturing and processing costs. In addition, chemical and physical analyses ensured that the application is highly resistant to disinfectants commonly used in hospitals. In summary, in a close development partnership, EMS provided the customer with cost and weight savings, as well as optimized use of resources and considerable added value.